|

Water Wheel Design

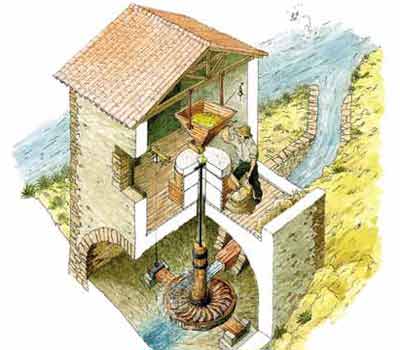

The water wheel design used most commonly in Great Britain and the United States was the vertical wheel rotating about a horizontal axle. In the Scottish highlands and parts of southern Europe mills often used a horizontal wheel (with a vertical axle). Below we detail the six types of water wheel design, showing a picture followed by the corresponding text.

Horizontal Wheel The wheel is usually mounted inside the mill building below the working floor. A jet of water is directed on to the paddles of the water wheel, causing them to turn. This is a simple system, usually used without gearing so that the axle of the waterwheel become the spindle of the mill. This system is sometimes called the Norse mill. In a sense it is the ancestor of the modern water turbine.

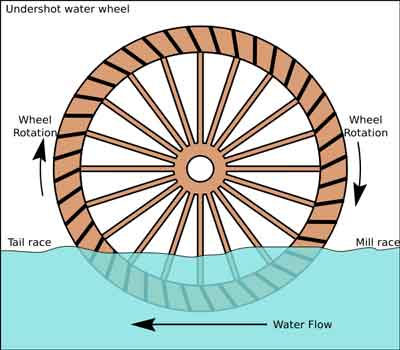

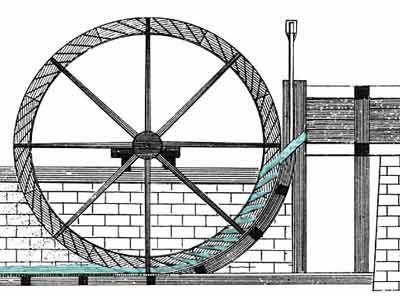

Undershot Wheel A vertically-mounted water wheel that is rotated by water striking paddles or blades at the bottom of the wheel is said to be undershot. This is generally the least efficient, oldest type of wheel.

It has the advantage of being cheaper and simpler to build, but is less powerful and can only be used where the flow rate is sufficient to provide torque. Undershot wheels gain no advantage from head. They are most suited to shallow streams in flat country. Undershot wheels are also well suited to installation on floating platforms. The earliest were probably constructed by the Roman general Belisarius during the siege of Rome in 537.

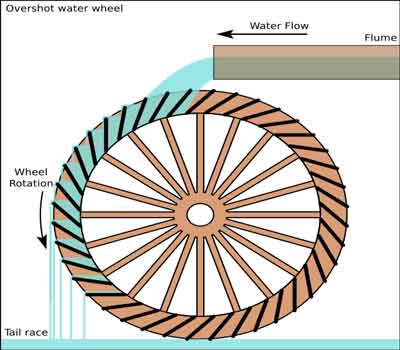

Overshot Wheel A vertically-mounted water wheel that is rotated by falling water striking paddles, blades or buckets near the top of the wheel is said to be overshot. In true overshot wheels the water passes over the top of the wheel, but the term is sometimes applied to backshot wheels where the water goes down behind the waterwheel. A typical overshot wheel has the water channeled to the wheel at the top and slightly to one side in the direction of rotation. The water collects in the buckets on that side of the wheel, making it heavier than the other "empty" side. The weight turns the wheel, and the water flows out into the tail-water when the wheel rotates enough to invert the buckets. The overshot design can use all of the water flow for power and does not require rapid flow. Unlike undershot wheels, overshot wheels gain a double advantage from gravity. Not only is the force of the flowing water partially transferred to the wheel, the weight of the water descending in the wheel's buckets also imparts additional energy. The mechanical power derived from an overshot wheel is determined by the wheel's physical size and the available head, so they are ideally suited to hilly or mountainous country. Overshot wheels demand exact engineering and significant head, which usually means significant investment in constructing a dam, millpond and waterways. Sometimes the final approach of the water to the wheel is along a lengthy flume or penstock.

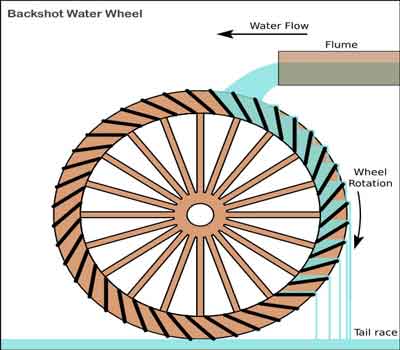

Backshot Wheel A backshot wheel (also called pitchback) is a variety of overshot wheel where the water is introduced just behind the summit of the wheel. It combines the advantages from breastshot and overshot systems, since the full amount of the potential energy released by the falling water is harnessed as the water descends the back of the wheel. A backshot wheel continues to function until the water in the wheel pit rises well above the height of the axle, when any other overshot wheel will be stopped or even destroyed. This makes the technique particularly suitable for streams that experience extreme seasonal variations in flow, and reduces the need for complex sluice and tail race configurations. A backshot wheel may also gain power from the water's current past the bottom of the wheel, and not just the weight of the water falling in the wheel's buckets.

Breastshot Wheel A vertically-mounted water wheel design that is rotated by falling water striking buckets near the centre of the wheel's edge, or just above it, is said to be breastshot. Breastshot wheels are the most common type in the United States of America and are said to have powered the American industrial revolution. Breastshot wheels are less efficient than overshot wheels and more efficient than undershot wheels. The individual blades of a breastshot wheel are actually buckets, as are those of most overshot wheels, and not simple paddles like those of most undershot wheels. Breastshot wheels are preferred for steady, high-volume flows such as are found on the fall line of the North American East Coast.

Hydraulic Wheel A recent development of the breastshot wheel is a hydraulic wheel which effectively incorporates a weir into the centre of the wheel. This was developed by the French inventeur Michael Fonfrede and is commercialised as the Aqualienne with an estimated hydraulic efficiency of 67% (max 76%). Overshot and backshot wheels are the most efficient water wheel design; a backshot steel wheel can be more efficient (about 60%) than all but the most advanced and well-constructed turbines. The development of the hydraulic water wheel design with their improved efficiency (>67%) opens up an alternative path for the installation of waterwheels in existing mills, or redevelopment of abandoned mills.

Return From Water Wheel Design To Home Page |